Imikhiqizo

I-Semi Automatic Vehicle Wheel Balancer

Isici

1.I-caliper ingakwazi ukukala ibanga

2.Ngomsebenzi wokuzilinganisa wokuzilinganisa

3.Tyre balance optimization

4.Ukulinganisa isondo lesithuthuthu nge-adaptha ngokuzithandela

5.Ifakwe umsebenzi wokuguqula ukusuka ku-intshi ukuya kumamilimitha kanye negremu ukuya ku-ounce

I-6.I-shaft yebhalansi ethuthukisiwe, ukuzinza okuhle, ifanele zonke izinhlobo zokulinganisa isondo eliyisicaba.

Ukucaciswa

| Amandla emoto | 0.25kw/0.32kw |

| Ukunikezwa kwamandla kagesi | 110V/220V/240V, 1ph, 50/60hz |

| I-Rim Diameter | 254-615mm/10”-24” |

| Ububanzi berimu | 40-510mm"/1.5"-20" |

| Ubukhulu. isisindo sesondo | 65kg |

| Ubukhulu. isondo ububanzi | 37"/940mm |

| Ukunemba kokulinganisa | ±1g |

| Isivinini sokulinganisa | 200rpm |

| Izinga lomsindo | <70dB |

| Isisindo | 112kg |

| Usayizi wephakheji | 1000*900*1100mm |

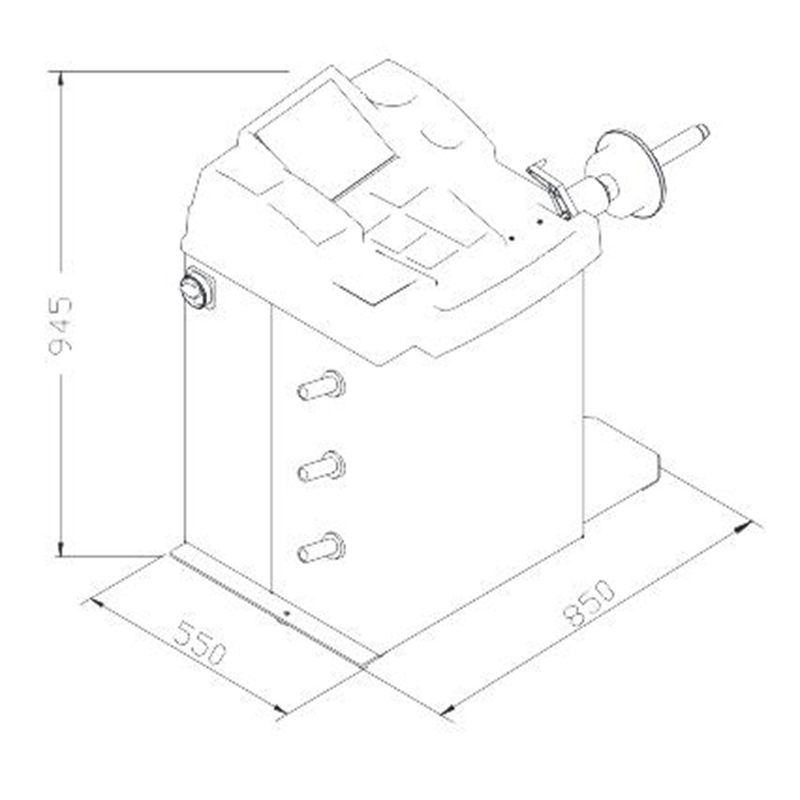

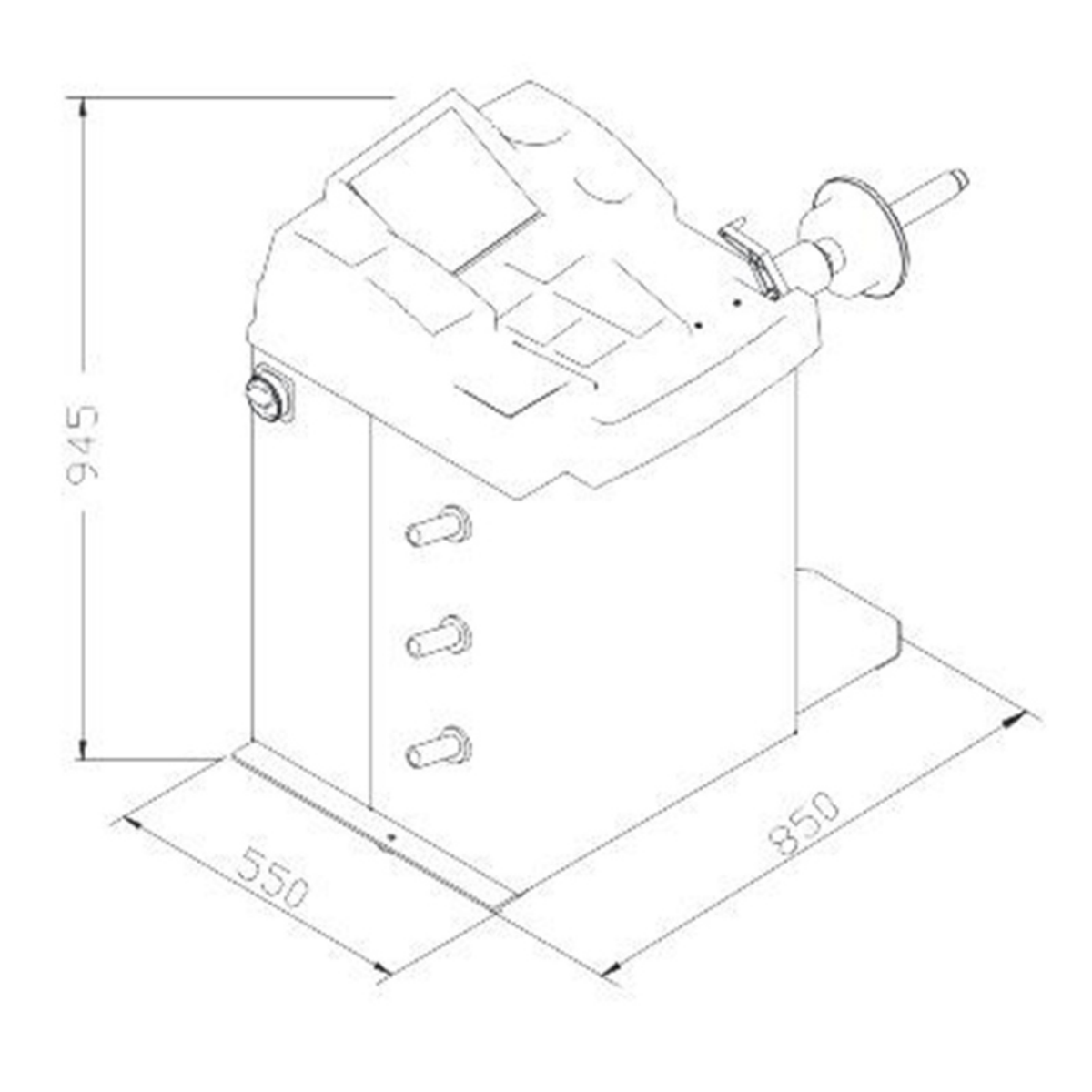

Umdwebo

Isimiso sokulinganisa amathayi

Uma amasondo emoto ezungeza ngesivinini esikhulu, kuzokwakheka isimo esishintshashintshayo sokungalingani, okubangela ukuthi amasondo kanye nesiteringi kudlikize ngesikhathi sokushayela. Ukuze ugweme noma uqede lesi simo, kuyadingeka ukwenza isondo lilungise ibhalansi yengxenye ngayinye yonqenqema ngokwandisa i-counterweight ngaphansi kwezimo eziguqukayo.

Okokuqala, qala i-motor ukushayela isondo ukuze lijikeleze, futhi ngenxa yemingcele engalingani, amandla e-centrifugal akhishwa isondo ku-piezoelectric sensor kuzo zonke izinkomba aguqulwa abe isignali kagesi. Ngokulinganisa okuqhubekayo kwesignali, uhlelo lwekhompiyutha luhlaziya isignali, lubala usayizi wenani elingalinganisiwe kanye nendawo encane yepharamitha, futhi iyibonise ohlelweni lwesikrini. Ukuze kuhlangatshezwane nesidingo sokungalingani okuncane, inzwa nesiguquli se-A/D ohlelweni kufanele sisebenzise imikhiqizo ezwela kakhulu nenemba kakhulu. Ngakho isivinini sekhompyutha nesivinini sokuhlola sesistimu sidinga ukuba phezulu.